|

|

3d Decorative Wall Panel Making Machine Manufacturer

|

Product Details:

Payment & Shipping Terms:

|

| Applicable Industries: | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Home Use, Retail, Construction Works | Showroom Location: | None |

|---|---|---|---|

| Condition: | New | Type: | Tile Forming Machine |

| Tile Type: | Colored | Use: | WALL |

| Production Capacity: | 8-12m/min | Voltage: | 380v |

| Dimension(L*W*H): | 2700*1600*2480mm | Weight: | 3.2T |

| Warranty: | 1 Year | Key Selling Points: | High Safety Level |

| Rolling Thinckness: | 0.3-0.8mm | Feeding Width: | 333 |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Marketing Type: | Ordinary Product | Warranty Of Core Components: | 1 Year |

| Core Components: | Motor, PLC | Control System: | PLC Control |

| Dimension(L*W*H):: | 2700*1600*2480mm | Color: | As Your Design |

| Mould: | You Can Choose As You Need | Cntrol: | Computer |

| Usage: | 3D Wall Panel | Advantage 1: | Offer The Material For 300*300 60 |

| Advantage 2: | The Type 600 Machine Can Produc | Advantage 3: | Fast Produce Speed |

| After Warranty Service: | Video Technical Support, Online Support, Field Maintenance And Repair Service | Local Service Location: | None |

| After-sales Service Provided: | Online Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Video Technical Support | Port: | Tianjin Port Or Qingdao Port |

3d decorative wall panel making machine manufacturer

Part 1 Instruction

This line include three machines:

1.1 Press machine with mold---for forming the panel

1.2 Cutting machine---for cutting the coil into pieces and also cut the four corners

1.3 Light steel roll forming machine---for forming the steel to fix the panels

Part 2 Specification for each machine

1.Press machine(with five molds for free)

1.1 100T/160T three-beam four-colum press machine

1.2 Final board/Plate size:300*300mm/600*600mm

1.3 Raw material width:330mm/660mm

1.4 Raw material thickness:0.3-0.4mm

1.5 Hydraulic station power:7.5kw

1.6 Quick exchange of molds

1.7 Eye protection device

1.8 Computer box:Delta PLC,counting function

1.9 Machine look like the following picture:

![]()

2.Cutting machine(with a small manual decoiler behind)

2.1 Main power:4kw

2.2 Cutting speed:50-60pcs/min

2.3 Electric driven

2.4 Volt:380V,50HZ,3phase

2.5 Machine look like the following picture:

![]()

3.Light steel roll forming machine

3.1 Station:12 rows forming rollers

3.2 Shaft diameter:40mm

3.3 Main power:2.2kw

3.4 Board thickness:12mm

3.5 Fly-saw cutting and chain transport

3.6 Machine look like the following picture:

![]()

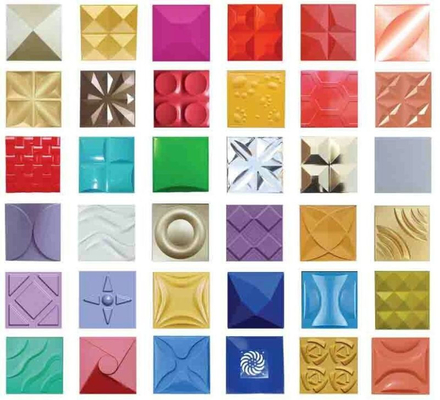

Part 3 Different designs for mold

3.1 For molds,there are 36 kinds for you to choose from,and you can send me your designed molds,we customize it for you.

3.2 The machine has 5 molds include,if you want more,price for each set of mold is USD900.

The following are some designs:

![]()

![]()

![]()

The design cataloge you can choose five molds,or send me your own design.

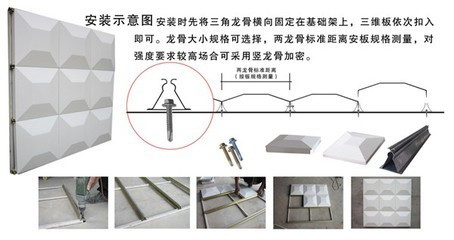

Manual picture:

![]()

Company Information:

Our company is a cold forming automatic production line manufacturer.which with greatest strength powerful technical force and complete sets of equipment.our company has been engaged in manufacture more than 15 years .we have developed more than ten series of steel rol forming machines.such as production lines for wall&roof sheet ,color steel tile ,C&Z shape production line ,glazed tile.floor board .all kinds of sandwich panels,curving machine for roof sheets .etc.

We passed authentication of ISO9001:2008. CE.

Technological innovation and management innovation is our relentless pursuit,we willfuly promote the product upgrading and development of the industry.

![]()

![]()

![]()

1. Q: What is the MOQ?

A: 1 set.

2. Q: What is the Delivery time?

A: Within 35 workdays.

3. Q: What is the Payment terms you can accept?

A: T/T or L/C.30% deposit,and before shipped we hope to receive the balance 70%.Also 100% L/C is accepted.

4. Q: What is the Warranty?

A: Within 2 years warranty .,All of the technical personnel are ready to serve you at any time.

5. Q:Can you make the machine according to my design or photo type?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us

6. Q: How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation of the machine.

3.Good after-sales service, its free of charge during the warranty period.

![]()

Contact Person: 15131750133

Tel: +8615131750133

-

New Design 3d Wall Panel Machines 3d Wall Panel Making Machine

-

high quality 3d Wall Panel Machine Forming Machine Manufacturer

-

Hot Sale 3D Wall Panel Machine 3D Wall Panel Roll Forming Machine

-

Haide Three Dimension Trigger 3D Wall Panel Machine With CE And ISO9001

-

decorative wall machine decoration tile 3d panels making 3d wall decorative machine

-

Hot sale 3d wall panel machines for advertisement