|

|

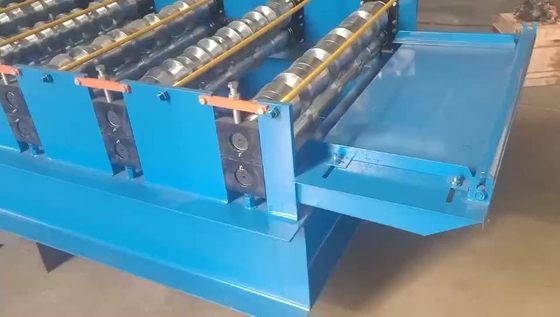

Hot Sale! IBR Roof And Wall Panel Forming Machine Trimdek Cold Forming Machine

|

Product Details:

Payment & Shipping Terms:

|

| Features: | Easy Operation | Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Farms, Restaurant, Home Use, Construction Works , Energy & Mining |

|---|---|---|---|

| Showroom Location: | None | Video Outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | New Product 2020 |

| Warranty Of Core Components: | 1 Year | Core Components: | PLC, Engine, Gearbox, Motor, Gear |

| Condition: | New | Automatic Grade: | Automatic |

| Production Capacity: | 8-12m/min | Voltage: | 380V |

| Power: | 3KW | Dimension(L*W*H): | 3030*1190*2500 |

| Weight: | 5 TON | Warranty: | 1 Year |

| Key Selling Points: | Long Service Life | Shaft Material: | C45steel |

| Shaft Diameter: | 70mm | Chains Transport: | 1" |

| Board: | 16mm | Frame: | 350H |

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts | Local Service Location: | None |

| After-sales Service Provided: | Online Support, Free Spare Parts, Video Technical Support | Port: | Tianjin |

Botou haide machinery manufacturing co.,ltd

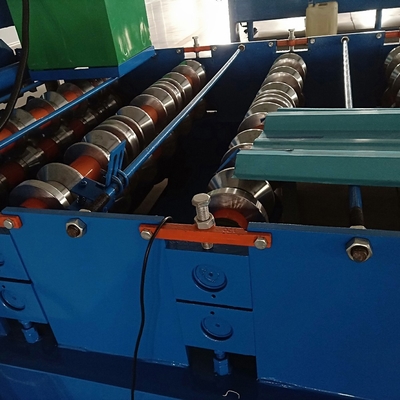

TRIMDEK® wall panel forming machine:

1.Main technical parameters:

1. Suitable material: color steel sheet or galvanized steel sheet

2.Thickness of raw material: 0.4-0.7mm

3. Yield strength of material: 235Mpa-345Mpa

4. Forming speed: about 20m/min

5. Power Requirement: Main motor power: 7.5KW (Depend on final design); Hydraulic station power: 2.2KW

6. Uncoilers loading capacity: Max. Capacity: 5000kgs (can be increased to be 10T)

7. Controlling system: Mitsubishi PLC & Converter

2.Material of Main Equipment:

1. Roller Material: High grade No.45 forged steel, with digital-controlled procession, Plated with hard chrome.

2. Active Shaft Material: High grade No.45 carbon wrought steel,which can improve the integrated mechanic feature of the shaft. Shaft diameter is 72mm.

3. Electric Elements: PLC control panel, transducer imported from Mitsubishi of Japan. Other elements from famous suppliers in China

4. Cutter blade: Cr12 mould steel with quenched treatment.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Our company is a cold forming automatic production line manufacturer.which with greatest strength powerful technical force and complete sets of equipment.our company has been engaged in manufac than ten years .we have developed more than ten series of steel rol forming machines.such as production lines for wall&roof sheet ,color steel tile ,C&Z shape production line ,glazed tile.floor board .all kinds of sandwich panels,curving machine for roof sheets .etc.

We passed authentication of ISO9001:2008. CE.

Our products are widely used in varilous industral factory civilian building .warehouse and easy steel building ,manufacturing and have features such as nice appearance and durable.

Seaworthy export standard packing for the machine. All machine parts are well fastened and fixed by blocks and wire ropes.

Normally one machine needs one 40 feet container for shipping.

![]()

Contact Person: 15131750133

Tel: +8615131750133

-

Ibr Wall Corrugated Roof Steel Sheet Glazed Tiles Making Machine

-

Roof Panel Roll Forming Machine Roof Sheet Metal Tile Making Machine Price

-

Steel Metal Sheet Roll Forming Ibr Roof Making Machine

-

IBR Roofing Panel Forming Machine IBR Roll Forming Machine

-

IBR Color Steel Sheet Roof Panel Making Roll Forming Machine

-

Hot Sale Roll Forming Machine Roofing Sheet Panel Making Machine Machinery