|

|

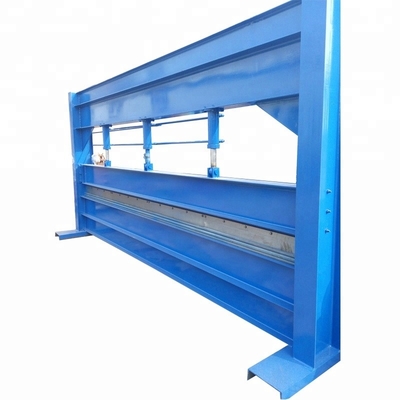

Metal Sheet Bending Machine Hot Selling In Factory Price

|

Product Details:

Payment & Shipping Terms:

|

| Applicable Industries: | Construction Works | Showroom Location: | None |

|---|---|---|---|

| Condition: | New | Type: | Tile Forming Machine |

| Tile Type: | Steel | Use: | ROOF |

| Production Capacity: | 0~6m/min | Voltage: | 380V 50HZ 3 Phase |

| Dimension(L*W*H): | 6500*1000*1300mm | Weight: | Aboutkg |

| Warranty: | 1 Year | Key Selling Points: | High-accuracy |

| Rolling Thinckness: | 0.3-0.8mm | Feeding Width: | 1000mm |

| Machinery Test Report: | Not Available | Video Outgoing-inspection: | Provided |

| Marketing Type: | New Product 2020 | Warranty Of Core Components: | 1 Year |

| Core Components: | Pump | Color: | Green,blue,grey,yellow |

| Transmission Model: | Hydraulic Drive | Blade Material: | Cr12 |

| Thickness Of Plate: | 0.3~0.8mm | Width Of Plate: | 6m |

| Fuel Tank Trip: | 200mm | The Fuel Tank Of Acts: | 90mm |

| After Warranty Service: | Online Support | Local Service Location: | None |

| After-sales Service Provided: | Online Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Video Technical Support | Port: | Tianjin |

metal sheet cutting and bending machine

1)Unique panel surface protection

2)High precision in forming and cutting

3)High utilization of material

4)PLC control system,easy operation

5)Hydraulic cutting,long operating

6)No noise,no shake

7)High quality,good after-sale service

8)reasonable price

Main technicial parameters

| Shearing length | ≤6m | |

| Folding thickness | 0.3~0.8mm | |

| Fuel tank trip | 200mm | |

| The fuel tank of acts | 90mm | |

| Surge of the pumping station | 1MP-40MP | |

| Pumping station electrical power | 4KW | |

| Installation dimension about(L*W*H) | 6.5*1*1.3M | |

| Main motor power | 3kw | |

| Blade material | Cr12 | |

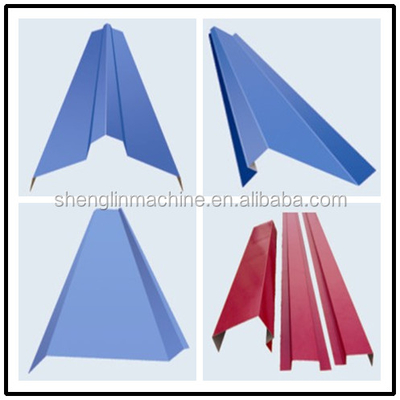

Pictures of steel bending machine

![]()

![]()

![]()

T/T, L/C, D/A, D/P, Western Union. Ali Trade Assurance.

1. One year, and we will provide the technical support for the whole life.

2. Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD100/person/day for salary.

3. Need one technician

4. Training time: one week (contains the time of installation and adjustment)

Packing and Shipping:

Packing Details: Main Machine: All rollers will be brushed anti-rusty oil and packed with water proof plastic film.

Control box: be packed with thick cardboard, and outer side thick water proof plastic film.

All parts inside container will be fixed very well which can keep safety and fixed for long time sea time transportation.

Shipping: Shipped in 35 days after payment.

![]()

Installation and Training:

1.If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

2.Without visiting, we will send you user manual and video to teach you to install and operate.

Our Service:

1.Customer's Design,Size,Color,Logo are accepted.

2.With 20 years professional manufacture experience.

3.Prompt Delivery&Competitive Price.

4.Main Makets: Middle East, Europe, North American, Africa, Southeast Asia.

After-sales Service:

1.We provide the technical support for whole life of our machines.

2.If buyer need the technican to go aboard ,we will arrange the technican.but the buyers should pay for all the cost including Visa,round trip ticket etc.

![]()

![]()

Botou Haide Machinery Manufacture Co.,Ltd was established in 1996.

Our products include: Glazed Tile Roll Forming Machine, Ridge Cap Roll Forming Machine,Roof Gutter Roll Forming Machine, Color Steel Roll Forming Machine, Russian Standard Steel Roll Forming Machine, Joint-hidden Roll Forming Machine, Downspout Forming Machine, C/Z Purlin Roll Forming Machine, Deck Floor Roll Forming Machine, Highway Guardrail Roll Forming Machine, Wind-Proof and Dust Control Plate Roll Forming Machine, Roller Shutter Door Roll Forming Machine, Stone Coated Roof Tile Production Line, Long-Span No Grider Roll Forming Machine, car panel,container panel, Storage Rack and Stand Column, Photovoltaic Supporter, Cable Tray Roll Forming Machine, Sandwich Panel Production Line, 3D Decorative Panel Machine, Advertisement Gusset Plate Machine and Bending &Cutting Machine & Decoiler, etc.

![]()

Contact Person: 15131750133

Tel: +8615131750133

-

Metal Sheet Hydraulic Bending Machine Used Cold

-

Automatic Steel Profile Plate Roof Bending Machine

-

Automatic Hydraulic Bending Machine Of Plate Bending

-

High Speed Steel Used Plate Bending Machine

-

Automatic Hydraulic Bending Machine Cold Steel 12 Meter

-

High Speed Cold Steel Door Frame Bending Machine